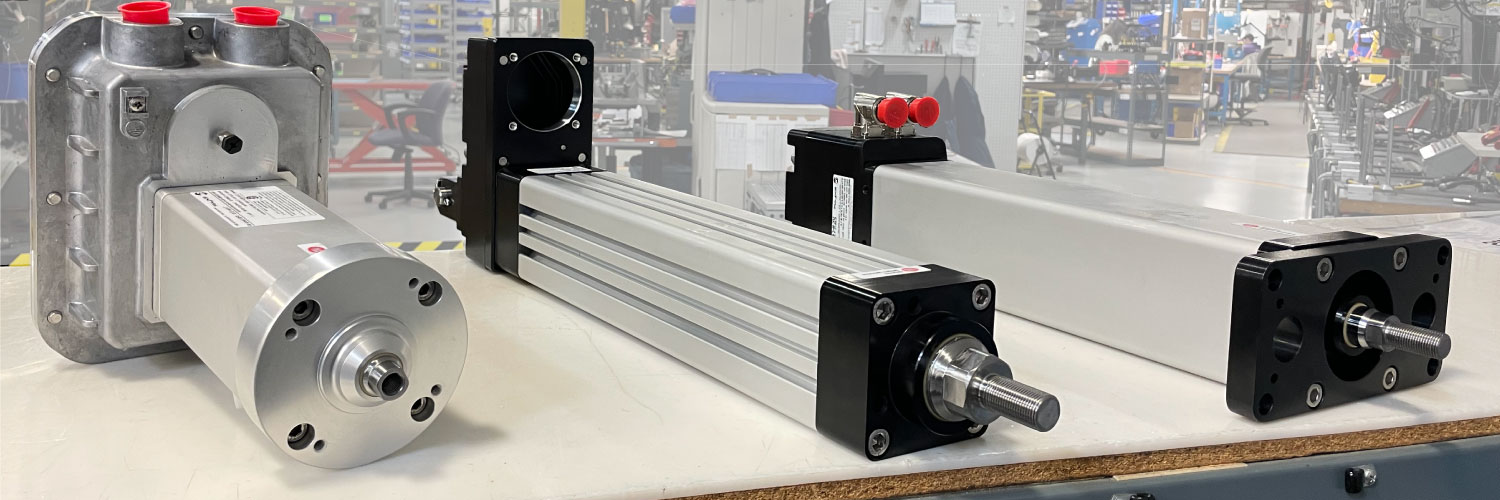

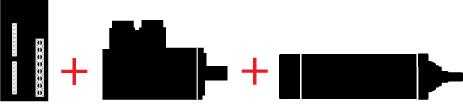

Exlar Electric Linear & Rotary Actuator Products

Exlar® electric actuators deliver a broad range of capabilities, power and performance in both linear and rotary configurations. Select from our extensive range of products to find a robust, reliable, and cost-effective solution for nearly any motion application.